Craftsmanship

Explore the world of Geovin and you will discover a rich heritage of craftsmanship, innovation, and passion for manufacturing excellence. Every detail is considered as we combine a new sense of urban modernism with traditional respect for solid craftsmanship and quality. We utilize the highest-quality materials, technologically advanced manufacturing processes and stringent quality-control measures. The entire manufacturing process is done locally in our 25,000 square foot facility in Vaughan, Ontario with more than 15 experienced employees.

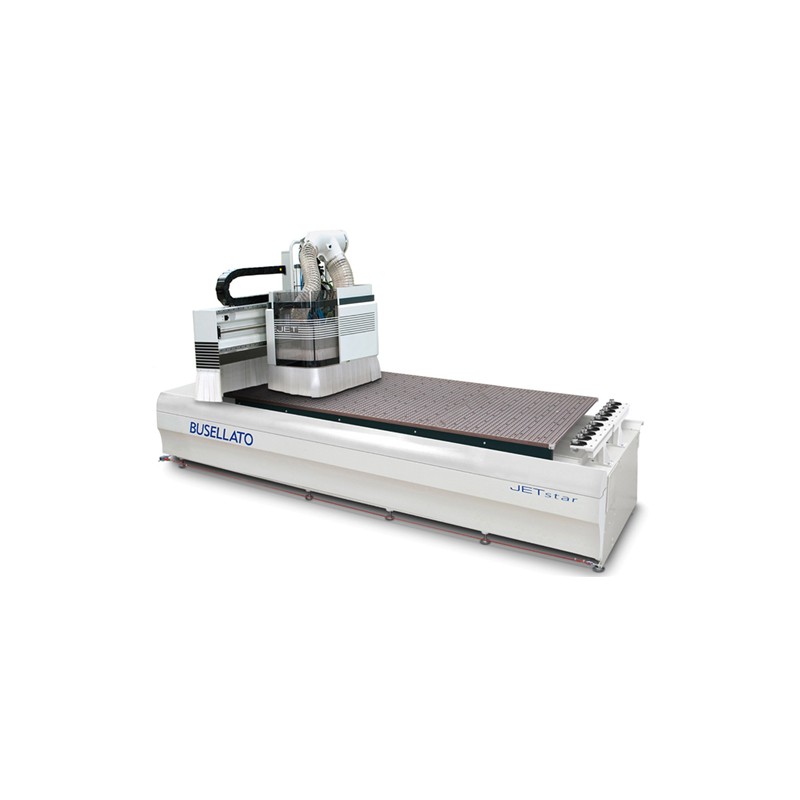

Highlights